Back

- About About

- Ergonomics Advice Ergonomics Advice

- Expert Opinion Expert Opinion

- Resources Resources

- Contact Contact

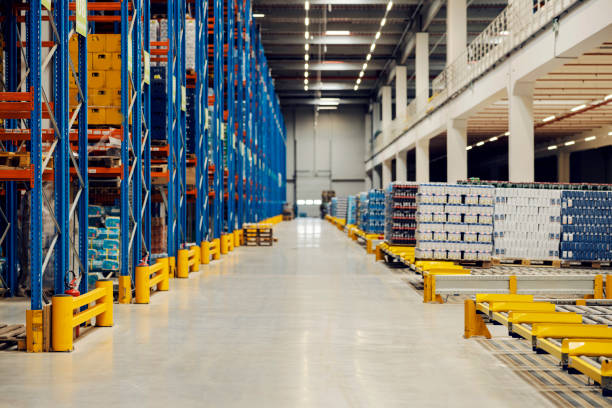

In the fast-paced climate of globalisation, consumer demands and distribution frenzies, we are seeing an increase in supply chain pressures. Optimising safety and efficiency is becoming increasingly paramount to keep up with these evolving demands. Ergonomics, the science of designing workplaces and tasks to fit the natural movements and capabilities of the human body, plays a crucial role in transforming industrial operations. The integration of ergonomic principles into these environments can safeguard the health and wellbeing of workers while also enhancing operational productivity.

Does the idea of more space and time sounds useful to your workplace? Read on to find out some ways ergonomics principles can significantly improve the safety and efficiency of your existing or new establishment.

One of the primary benefits of ergonomics is the reduction of workplace injuries.

In warehousing and manufacturing, workers often engage in prolonged and repetitive tasks, heavy lifting, and awkward postures. These activities can lead to

musculoskeletal disorders (MSDs), which are among the most common work-related injuries.

By designing workstations, warehouse layout, tools, and tasks that accommodate natural body movements and minimise strain, ergonomics helps in significantly lowering the incidence of MSDs.

Designing workplace layout and systems of work using ergonomic principles can assist in the strategic planning of processes to gain maximum usage of space, streamline workflow, minimise lag times and improve efficiencies through the entire process. By analysing the movements required to complete tasks and arranging stock, tools and materials within easy reach, companies can minimize unnecessary motions and reduce cycle times. This leads to more efficient workflows and faster processing times, contributing to higher output and better utilisation of resources. Ergonomic tools that reduce the effort required to perform tasks can speed up processes and reduce the risk of errors.

Every warehousing and manufacturing environment is unique, with specific tasks, tools, and challenges. Ergonomics allows for customised solutions tailored to the specific needs of different workplaces. Through ergonomic assessments, our consultants can identify risk factors and recommend changes that are most effective for a particular setting. This personalised approach ensures that ergonomic interventions provide maximum benefit, addressing the specific issues faced by each business.

A workplace that prioritises ergonomics demonstrates a commitment to employee wellbeing. This can lead to higher job satisfaction and improved morale. Employees are more likely to stay with a company that values their health and comfort, reducing turnover costs and retaining skilled workers. Happy employees are also more engaged and motivated, contributing to a positive workplace culture and enhanced overall performance.

By clicking Stay Informed you’re confirming that you agree with our Terms and Conditions.